Cubic Boron Nitride mono-crystalline is one kind of super abrasives that has the most thermal stability and its hardness is only second to the diamond. Not like a diamond, due to the combination of CBN’s toughness, chemical, and thermal stability, CBN is widely used for grinding ferrous alloys and superalloy materials.

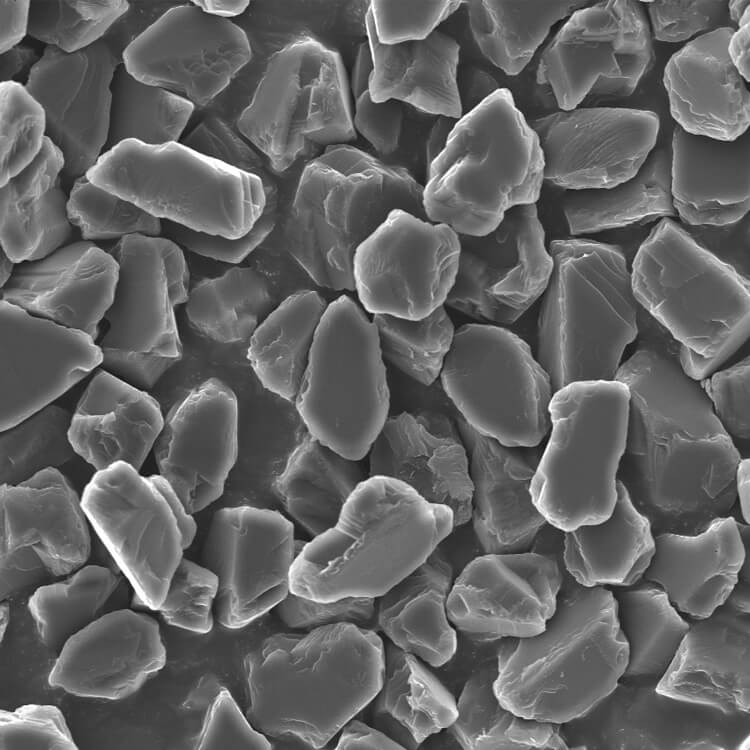

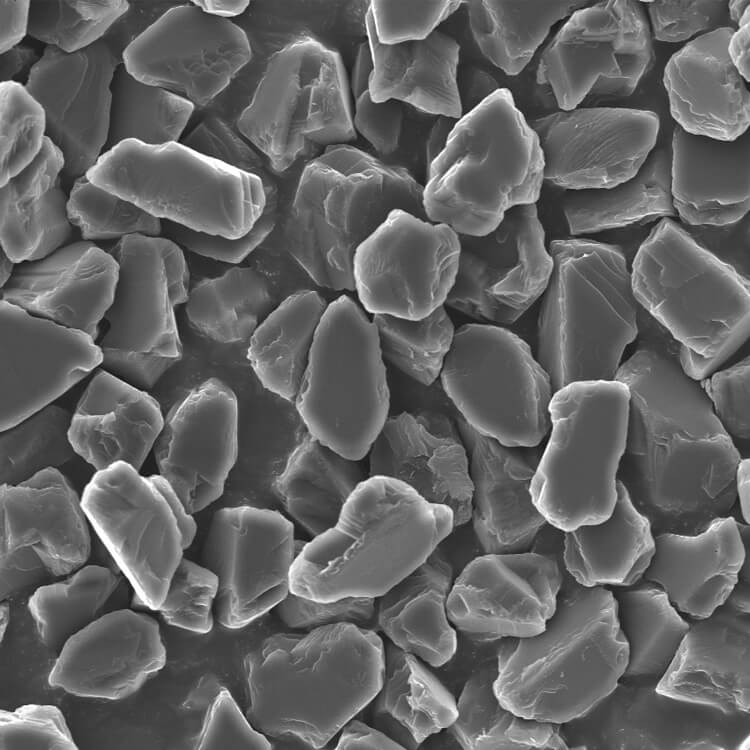

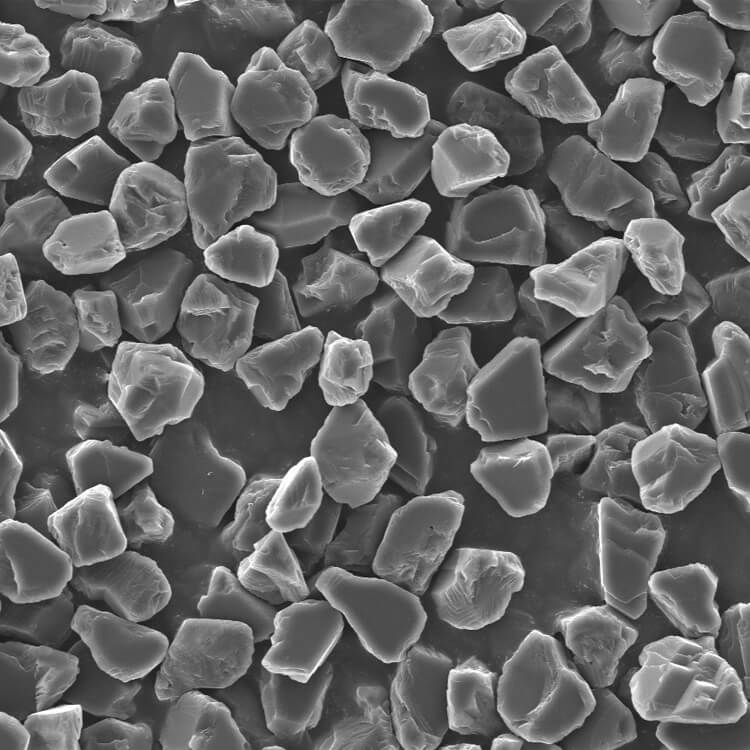

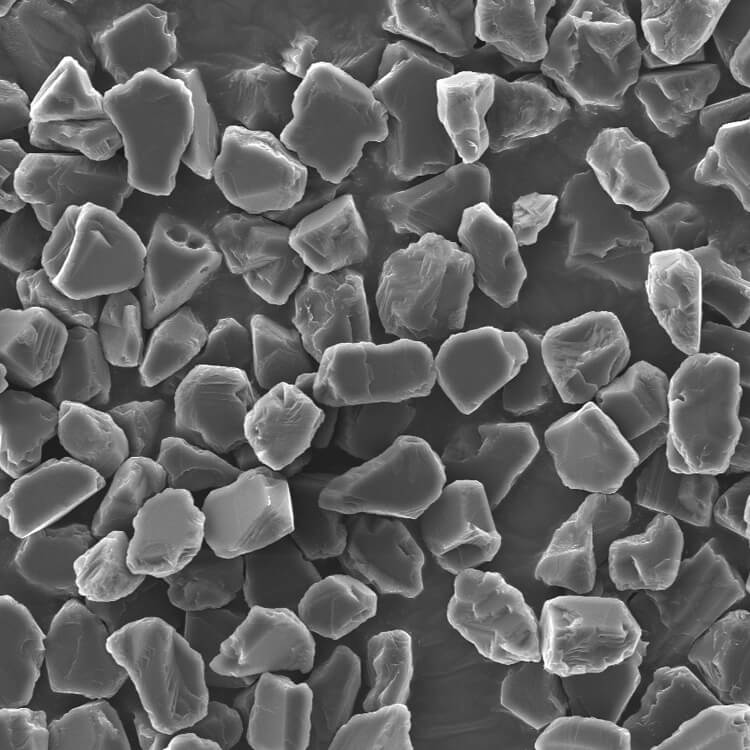

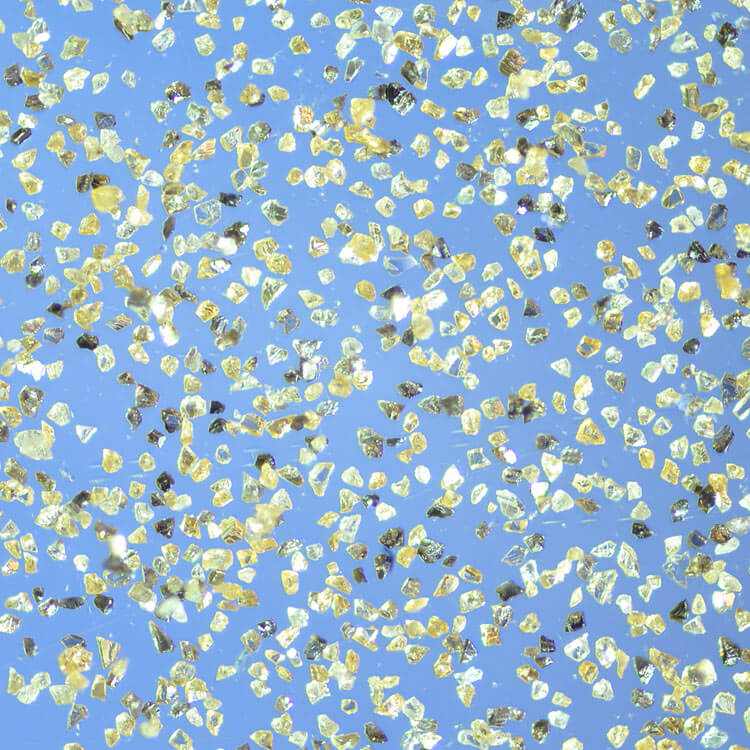

Cubic boron nitride Micron powder refers to cubic boron nitride abrasive particles with a particle width smaller than 36/54 microns. It is made of cubic boron nitride mono-crystal abrasive grains, which are crushed and reshaped, and produced by a special process. Abbreviated as CBN micron powder, it has high crystal purity, good thermal stability, good self-sharpening, and high grinding efficiency. Use it to obtain a precise and high-finish working surface, which can make your products have higher quality.

| GB Standard | USA (ISO) Standard | Japan Standard (Mesh#) | Medium (D50μm) |

| W0.2 | 0-0.2 | 80000 | 0.1 |

| W0.25 | 0-0.25 | 60000 | 0.11-0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20-0.30 |

| W1 | 0-1 | 15000 | 0.6-0.8 |

| W1.5- | 0-2 | 13000 | 1 |

| W1.5 | 1-2 | 12000 | 1.1-1.3 |

| W2.5 | 1-3 | 10000 | 1.6-1.8 |

| W3 | 2-3 | 7000 | 1.9-2.1 |

| W3.5 | 2-4- | 6500 | 2.2-2.6 |

| W3.5 | 2-4 | 6000 | 2.6-3.0 |

| W4 | 2-5 | 5000 | 3.1-3.4 |

| W5 | 3-6 | 4000 | 3.5-4.2 |

| W6 | 4-6 | 3500 | 4.4-5.0 |

| W7 | 4-8 | 3000 | 5.0-6.0 |

| W10 | 4-9 | 2500 | 6.1-6.5 |

| W10 | 5-10 | 2000 | 6.5-7.3 |

| W10 | 6-12 | 1800 | 7.3-8.3 |

| W12 | 8-12 | 1600 | 8.3-9.0 |

| W14 | 7-14 | 1500 | 9.1-10.5 |

| W14 | 8-16 | 1300 | 10.0-12.0 |

| W20- | 10-20 | 1200 | 12.5-15.0 |

| W20 | 12-22 | 1000 | 15.0-17.0 |

| W20+ | 15-25 | 800 | 18.0-20.0 |

| W28 | 20-30 | 700 | 20-23 |

| W28+ | 22-36 | 600 | 23-26 |

| W40- | 20-40 | 500 | 26-29 |

| W40 | 30-40 | 450 | 29-32 |

| W40+ | 35-45 | 400 | 32-36 |

| W50 | 36-54 | 37-43 | |

| 325/400 | 320 | 43-48 | |

| 270/325 | 280 | 48-55 | |

| 230/270 | 240 | 56-64 | |

| 200/230 | 200 | 65-73 | |

Cubic boron nitride (CBN) micron powder is used for precision grinding, lapping, polishing, and superfinishing to achieve high-precision machining surfaces. It is suitable for resin, metal, ceramic, and other binder systems, and can also be used to produce polycrystalline composite sheet sintered bodies, and can also be used as loose abrasive particles and abrasive pastes.

Black cubic boron nitride has excellent chemical and physical properties, such as high hardness, high thermal stability, and chemical inertness second only to diamond. As a super-hard abrasive, it has been widely used in processing fields in different industries, and it is now becoming Indispensable and important material for industries such as automobiles, aerospace and aviation, mechatronics, microelectronics, etc., have also received great attention from industrialized countries.

In addition to the static high-pressure catalyst method, there are many methods for synthesizing CBN, such as static high-pressure direct conversion method, dynamic impact method, vapor deposition method, etc. Some methods such as the vapor deposition method develop rapidly. But so far, the main method of industrial synthesis of CBN is still the static high-pressure catalyst method, and the synthesis of CBN is also mainly focused on this aspect.