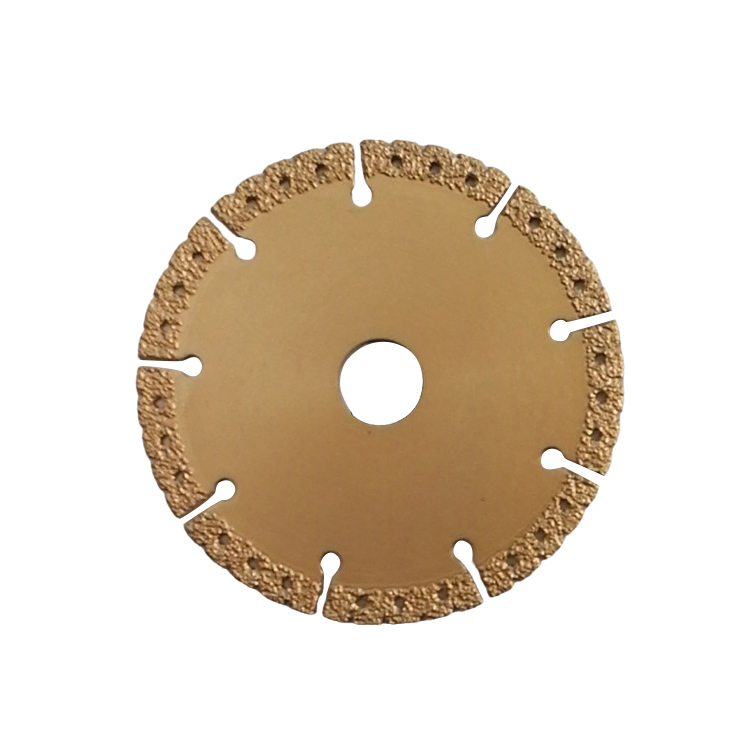

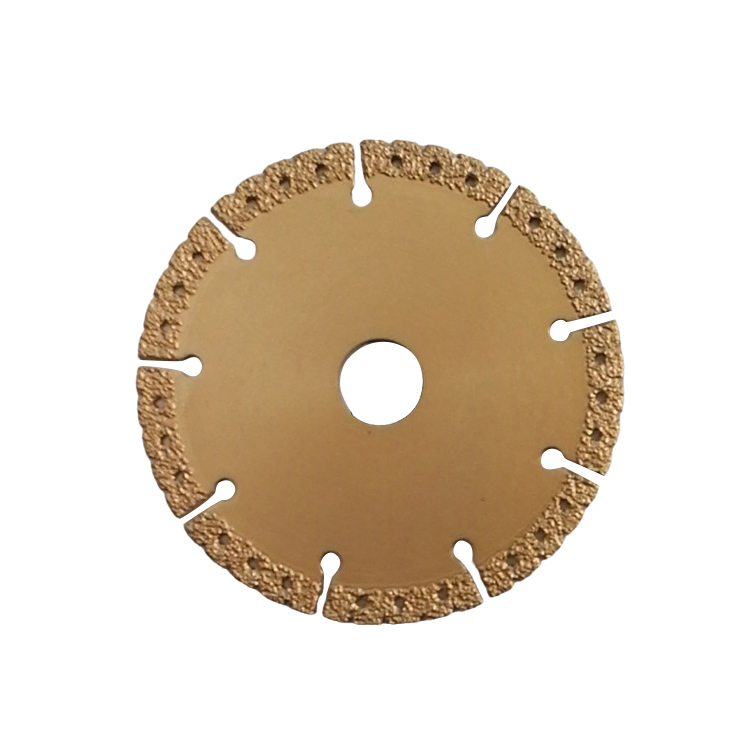

Vacuum Brazing is a material joining process that directly bonds diamond to the blade. Based on the whole industrial technology advantages from raw materials to mature tools, UHD brazed tools, with superhard grits brazed on the base surface can make the abrasives work directly to the subject, more and higher edges improve working efficiency.

The diamond cutting and grinding disc can be applied as cutting disc and grinding disc at the same time which is widely used in foundries. The discs are safe and reliable, with the efficiency can be improved by 3 times, and working life extend by 100 times compared to traditional resin bond tools. With minimal dust & odor and size retaining, the tools are the best choice for metal processing to replace the traditional resin tools and common ceramics abrasives tools.

UHD diamond cutting and the grinding disc have full range and the product features high sharpness, durability, no dust in the work site, safety, and no piece breaking, which is the best choice for the foundry enterprise grinding operation. The lifetime can be two times more than electroplated diamond tools.

The multifunctional diamond cutting and grinding disc are well applied on gray cast iron, ductile cast iron, small steel parts, hard metal, as well as on stones such as granite, marble, crystal stone for coarse grinding, and semi-grinding processing. It’s the ideal and high efficient tool to cut and grind casting head, ductile iron edges and surface burrs, polished, etc.

ZSG100, ZSG125, ZSG150, ZSG180, ZSG230

| Specification | Workpiece | Worlpiece material | Parameter |

Lifetime |

| ZSG180 | Fan shell | Gray iron 300 | RPM 4000 | 3-4 days |

| Corundum resin disc | Fan shell | Gray iron 300 | RPM 4000 | 2 hours |

| Specification | Size | RPM | Applicable object |

| ZSG230 | 230*2.5*22.23 | 6600 | Cast iron |

| ZSG180 | 180*2.5*22.23 | 8600 | Cast iron |

| ZSG150 | 150*2.0*22.23 | 9200 | Cast iron |

| ZSG125 | 120*1.6*22.23 | 10200 | Cast iron |

| ZSG100 | 100*1.5*16 | 12000 | Cast iron |