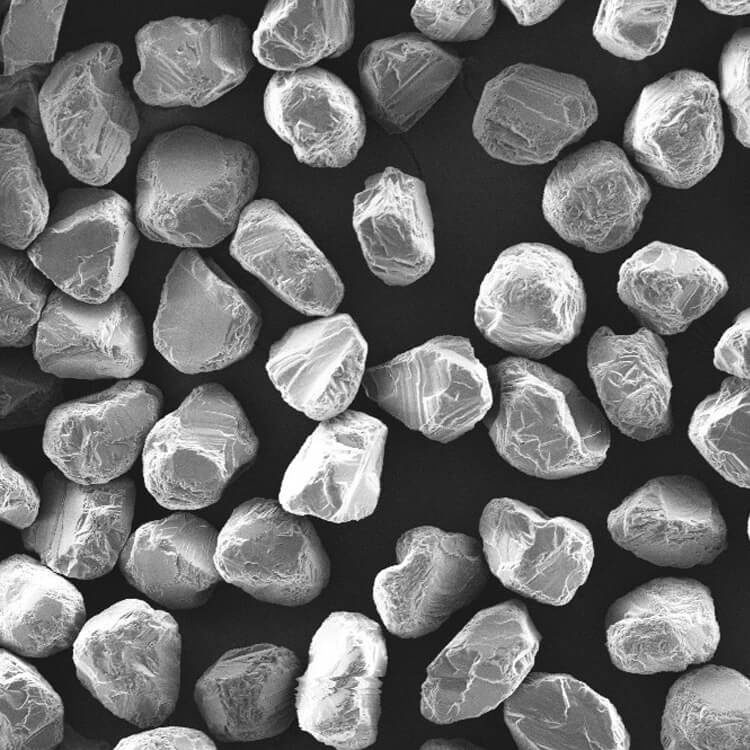

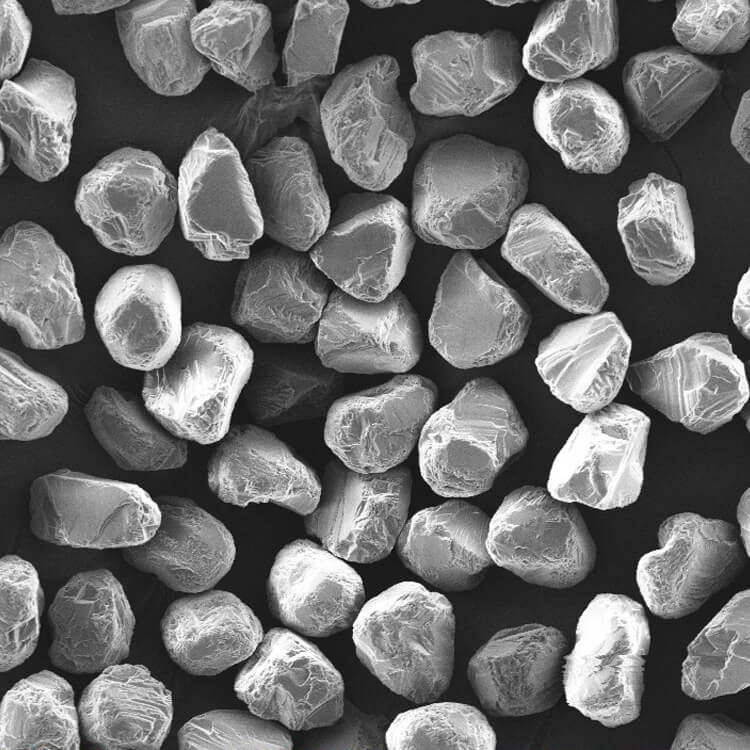

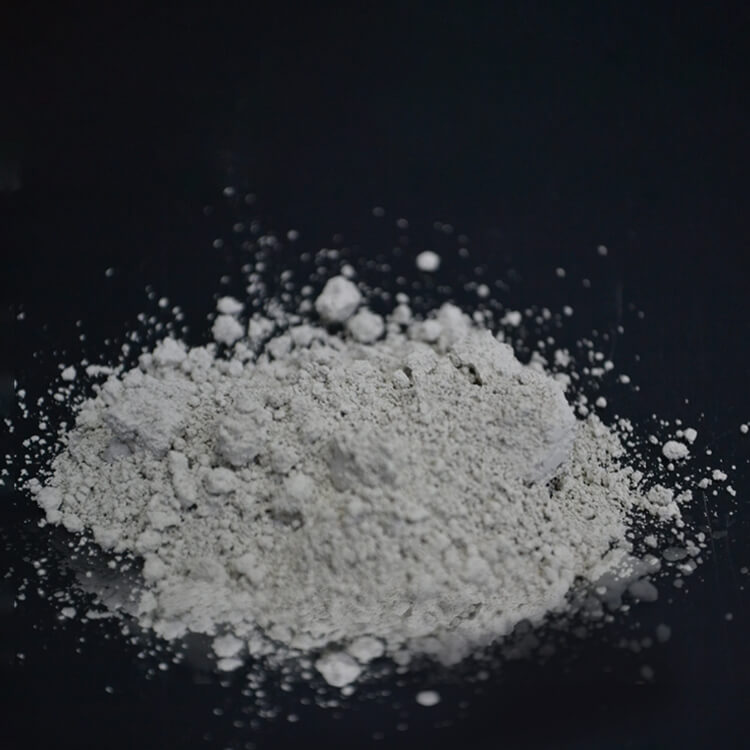

Diamond micron powder refers to diamond particles finer than 36/54 microns, including single crystal diamond powder and polycrystalline diamond micron powder. Due to the large output of single-crystal diamond powder and wide application fields, the industry generally refers to diamond powder specifically for single crystal diamond powder. Single crystal diamond powder is a synthetic diamond single crystal abrasive grain produced by static pressure, which is crushed and shaped and is super hard. The material is produced by a special process method. The diamond powder has high hardness and good wear resistance and can be widely used in cutting, grinding, drilling, polishing, etc. It is an ideal raw material for grinding and polishing hard alloys, ceramics, gems, optical glass, and other high-hardness materials. Diamond powder products are tools and components made by processing diamond powder.

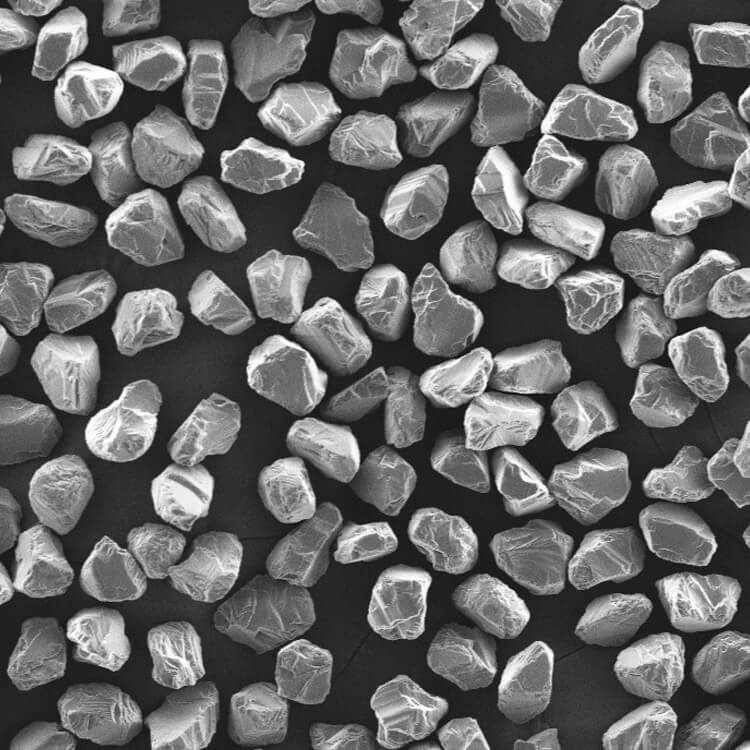

Polycrystalline diamond powder is made of graphite using a unique directional blasting method. The shock wave of the directional blasting of a high-explosive explosive accelerates the flight of the metal flying piece and hits the graphite piece to cause the graphite to be converted into the polycrystalline diamond. Its structure is very similar to that of natural carbonado diamond. Its particles are composed of tiny diamond grains combined through unsaturated bonds. It has good toughness. However, due to the limitation of synthesis conditions of polycrystalline diamond powder, the manufacturer is very less, the product cost is relatively higher, and the particle size that can be provided in batches is not greater than 10 microns, which limits its application fields.

Diamond micron powder is the hardest ultrafine abrasive. It has been widely used in machinery, aerospace, optical instruments, glass, ceramics, electronics, petroleum, geology, and military industries. It is used for grinding and polishing cemented carbide ceramics, gems, optical glass, etc. Ideal material for hard materials. Generally, 0-0.5 micron diamond powder to 6-12 micron diamond powder is used for polishing; 10-15 micron to 22-36 micron is used for grinding, and the coarser 12-22 micron is used for fine grinding.

| GB Standard | USA (ISO) Standard | Japan Standard (Mesh#) | Medium (D50μm) |

| W0.2 | 0-0.2 | 80000 | 0.1 |

| W0.25 | 0-0.25 | 60000 | 0.11-0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20-0.30 |

| W1 | 0-1 | 15000 | 0.6-0.8 |

| W1.5- | 0-2 | 13000 | 1 |

| W1.5 | 1-2 | 12000 | 1.1-1.3 |

| W2.5 | 1-3 | 10000 | 1.6-1.8 |

| W3 | 2-3 | 7000 | 1.9-2.1 |

| W3.5 | 2-4- | 6500 | 2.2-2.6 |

| W3.5 | 2-4 | 6000 | 2.6-3.0 |

| W4 | 2-5 | 5000 | 3.1-3.4 |

| W5 | 3-6 | 4000 | 3.5-4.2 |

| W6 | 4-6 | 3500 | 4.4-5.0 |

| W7 | 4-8 | 3000 | 5.0-6.0 |

| W10 | 4-9 | 2500 | 6.1-6.5 |

| W10 | 5-10 | 2000 | 6.5-7.3 |

| W10 | 6-12 | 1800 | 7.3-8.3 |

| W12 | 8-12 | 1600 | 8.3-9.0 |

| W14 | 7-14 | 1500 | 9.1-10.5 |

| W14 | 8-16 | 1300 | 10.0-12.0 |

| W20- | 10-20 | 1200 | 12.5-15.0 |

| W20 | 12-22 | 1000 | 15.0-17.0 |

| W20+ | 15-25 | 800 | 18.0-20.0 |

| W28 | 20-30 | 700 | 20-23 |

| W28+ | 22-36 | 600 | 23-26 |

| W40- | 20-40 | 500 | 26-29 |

| W40 | 30-40 | 450 | 29-32 |

| W40+ | 35-45 | 400 | 32-36 |

| W50 | 36-54 | 37-43 | |

| 325/400 | 320 | 43-48 | |

| 270/325 | 280 | 48-55 | |

| 230/270 | 240 | 56-64 | |

| 200/230 | 200 | 65-73 | |

Diamond micron powder is widely used in machinery, aerospace, optical instruments, glass, ceramics, electronics, petroleum, geology, and military industries. It is an ideal material for grinding and polishing hard alloy ceramics, gems, optical glass, and other high-hard materials.

Polycrystalline diamond powder utilizes good toughness and can maintain high grinding force while not prone to scratches during the grinding and polishing process. It is widely used in the grinding and polishing of various hard materials such as optical crystals, ceramics, and super-hard alloys.